Solutions

Three-Way Catalytic Converters

3-Way Catalytic Converters control exhaust emissions from stoichiometric CNG, LPG and gasoline engines. 3-Way catalytic converter technology cannot be used on lean-burn CNG or diesel engines (see SCR for diesel NOx control). Three-way catalytic mufflers are the most effective way of controlling carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) emissions with simultaneous reductions of up to 90-99%.

Typical Conversion Efficiencies:

- NOx : 90-99%

- CO : 90-99%

- HC : 50-90%

- CH20 : 80-95%

- HAPs : 80-95%

Three-Way Catalytic Converter Applications:

- Cars, Trucks & Busses that use Gasoline, LPG, and Natural Gas

- Off-Road Stationary engines including Heavy Duty for mining, earth moving, and Construction.

Diesel Retrofit Systems

Logical Clean Air Solutions has partnered with over 160+ emissions equipment manufacturers for advanced engineering, prototyping, and manufacturing of Diesel Retrofit Systems. These systems can be retrofitted on trucks and buses, off-highway vehicles, and stationary diesel engines. We find the most cost effective way to reach your emissions regulations.

Diesel Oxidation Catalysts (DOC's) - are catalytic converters designed specifically for diesel powered engines and equipment. DOC's reduce Carbon Monoxide (CO) and Hydrocarbons (HC) including the Soluble Organic Fraction (SOF) of Diesel Particulate Matter (DPM). DOC's are simple, inexpensive, maintenance free and suitable for all types and applications of diesel engines.

Logical Clean Air Solutions offers a line of diesel oxidation catalyst (DOC) converters specifically designed for large, stationary industrial engines. Oxidation converters are used for lean-burn engines (diesel/CNG) to meet emission standards for carbon monoxide (CO), hydrocarbons (HC) and the SOF fraction of diesel particulate matter (DPM/PM).

Diesel Particulate Filter (DPF's) - are highly effective in the elimination of particulate matter (PM10) or soot from diesel exhaust. Logical offers a variety of filter coatings and designs, depending on the engine application and duty cycle. Contact a representative for assistance with choosing the right filter for your application.

Features

- Heavy gauge stainless steel construction.

- Replaces the OEM muffler in most vehicles and includes customized exhaust tube or pipe connections.

- Advanced Cordierite wall flow filter media.

- Removable end disks allow easy access for filter cleaning.

- Backpressure monitor with operator indicator lights.

Supported Brands

- Caterpillar

- Freightliner

- Isuzu

- Mitsubishi/Fuso

- Sterling

- Cummins

- Hino

- Kenworth

- Paccar

- Volvo

- Mack

- Peterbilt

- Western Star

- Detroit Diesel Int.

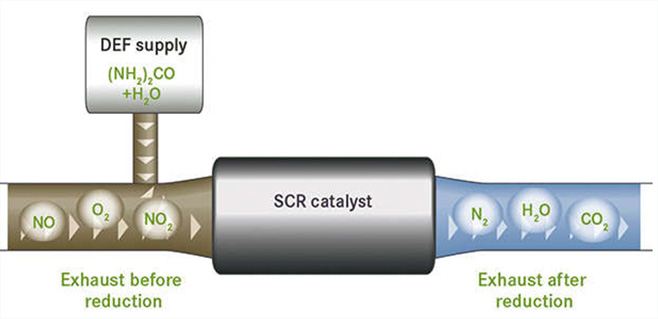

Selective Catalytic Reduction (SCR's)

An SCR system is a reliable, cost-effective technology designed to control nitrogen oxides (NOx) emissions from medium and heavy-duty diesel engines in on-road, non-road and stationary applications.

Mobile SCR System

An SCR for mobile applications is a retrofit solution that offers superior NOx reduction capabilities. Our SCR system capabilities do not change or alter the design or operation of your vehicle.

Our selective catalytic Reduction (SCR) systems deliver near-zero emissions of nitrogen oxides (NOx). The urea solution is carried in an onboard tank and injected upstream of the SCR catalyst.

Each SCR is custom designed for each intended application to provide optimum performance. As an additional option, Logical can also include either an active regeneration diesel particulate filter, or a passive catalyzed diesel particulate filter.

Stationary SCR system

Designed for flexibility and adaptability, Our Stationary SCR System offers three NOx control options:

- Load-based curve

- Closed-loop feedback

- Load-based curve with NOx trim

Using urea (or aqueous ammonia), the SCR systems achieve NOx reductions of 90%+ for diesel or gas engines. Urea serves as the ideal reducing agent since it can be shipped and stored easily and is colorless, odorless, nontoxic and bio-friendly. Both aqueous solutions of ammonia and urea have proven their suitability for the catalytic reduction of NOx in many applications. The advantage of the SCR process is the achievement of high NOx reduction rate and low ammonia slip. (Ammonia "slips" through the catalyst unreacted.)

SCR Systems for Diesel and Natural Gas engines can be used in applications for:

- Distributed Power Generation

- Cogeneration Plants (CHP)

- Gas Compression & Transmission

- Oil & Gas Exploration

- Industrial & Chemical Industries

- Marine & Ferry Power

Owners of diesel and natural gas engines are under constant pressure to reduce emissions. Whether driven by new regulation or local permitting authorities, lower emissions are an important part of almost every stationary engine project.

We understand emissions control systems are major project expenses. Because we supply hundreds of units per year, we can take advantage of common designs and volume pricing, making the Logical system one of the most cost-competitive in the market.

Regenerative Catalytic/Thermal Oxidation (RCO)

A Regenerative Catalytic Oxidizer (RCO) & Regenerative Thermal Oxidizer (RTO) destroys Hazardous Air Pollutants (HAPs), Volatile Organic Compounds (VOCs) and odorous emissions that are often discharged from industrial processes. The RCO achieves emission destruction through the process of thermal and catalytic oxidation, converting the pollutants to carbon dioxide and water vapor while reusing the thermal energy generated to reduce operating costs.

What differentiates the RCO from a standard RTO system is the addition of catalyst. It allows destruction of harmful compounds to occur at lower temperatures.

The Logical RCO/RTO Advantage:

- Zero leakage, dual-disk Poppet valve design achieves 99+% destruction efficiency without a puff chamber or reliability concerns

- Regulatory Compliance Guaranteed

- System flexibility addresses a wide range of process conditions and easily controls multiple sources

- Customized ceramic media with true thermal energy recovery up to 97%

- Low pressure drop reduces electrical consumption

- Competitive capital equipment cost

- Small equipment footprint